Nitromater – Now Explore Together In 2024!

Nitromater, a cutting-edge technology with a wide range of applications, has revolutionized various industries with its unique capabilities.

Nitromater is not like your favourite energy drink; instead, it’s a special tool used in different industries. Its job is to check and manage the levels of nitrate, kind of like a detective for nitrates.

This article delves into the essence of nitromater, exploring its key features, historical evolution, diverse applications, benefits, challenges, prospects, and the profound impact it has on various sectors.

History And Development Of Nitromater – Don’t Miss Out!

Humble Beginnings:

The story of Nitromater starts with simple beginnings, perhaps as basic as a stick in the mud in its early days. As technology advanced, the Nitromater’s journey progressed beyond its modest origins, marking the beginning of a remarkable evolution that would transform it into a sophisticated and precise device.

Evolution over Time:

From those initial stages, Nitromaters have undergone a remarkable evolution, transforming into advanced instruments that can precisely analyze nitrate levels. This evolution involved the integration of cutting-edge technologies, allowing these devices to transition from rudimentary tools to highly advanced instruments capable of intricate analysis.

Advancements in Technology:

Technological progress has played a crucial role in shaping Nitromater’s journey. Like a tech-savvy superhero upgrading their gear, Nitromaters have seen significant advancements, making them sophisticated and precise detectors of nitrate concentrations.

These advancements include the integration of sophisticated sensors, data analysis algorithms, and enhanced materials, transforming Nitromaters into highly efficient and reliable detectors of nitrate concentrations.

Scientific Innovation:

The history of Nitromater is a tale of scientific wizardry, showcasing how innovation has propelled it from rudimentary forms to its current high-tech state. The evolution of the Nitromater is a testament to the ingenuity of those who sought to improve and refine its capabilities over time.

Efficiency and Reliability:

Technological milestones throughout the years have not only added sophistication but have also made Nitromaters efficient and reliable tools for detecting and measuring nitrate concentrations accurately.

Key Features And Components Of Nitromater – You Should Know!

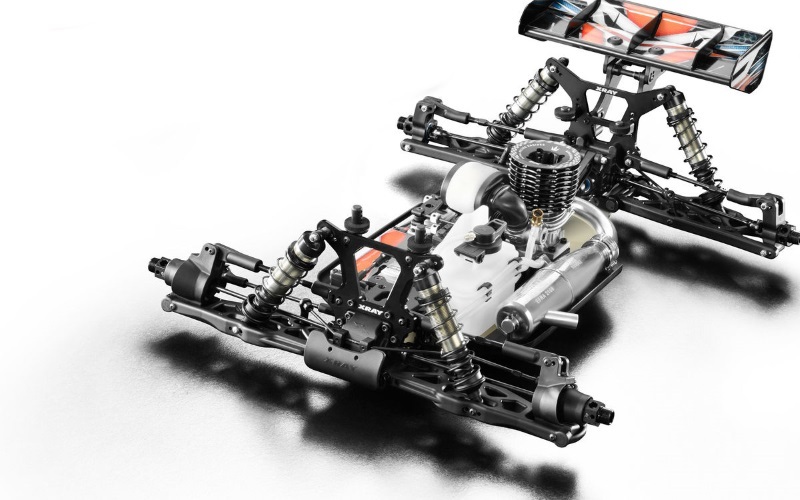

Sensors: Nitromaters are equipped with sensors as a fundamental component, allowing them to detect and measure nitrate concentrations accurately.

Analyzers: The analyzers in Nitromaters play a crucial role in processing the data collected by sensors, contributing to the device’s ability to provide precise measurements.

Data Display Units: These units serve as the interface between the Nitromater and its user, displaying the analyzed data in a comprehensible format.

Chemical Reactions: The operational magic of Nitromater involves a series of chemical reactions. These reactions are essential in the detection and measurement of nitrate concentrations in liquids.

Sensors and Algorithms: Nitromaters rely on sensors to collect data during chemical reactions. Algorithms then process this data, ensuring accurate and rapid measurement of nitrate levels.

Compact Design:

Mini-Laboratory Concept: Nitromaters embody a mini-laboratory concept by incorporating sensors, analyzers, and data display units into a single sleek device. This design allows for portability and efficiency in measuring nitrate concentrations.

Read: 9aniwave – Understanding Its Community and Creativity!

Applications And Uses Of Nitromater – Let’s Find Out!

The Nitromater, with its nitrate-detecting capabilities, finds widespread application across various real-world scenarios, serving as a versatile tool with significant implications.

Industrial Applications:

In industries such as agriculture, water treatment, and food production, Nitromaters play a pivotal role in monitoring and controlling nitrate levels. Acting as vigilant guardians, these devices ensure that nitrate content in industrial processes remains within acceptable limits.

This application not only safeguards the quality of agricultural products and water resources but also contributes to the overall efficiency and compliance of industrial operations.

Research and Scientific Uses:

Within the realms of research and science, Nitromaters emerge as invaluable tools for diverse purposes. Scientists and researchers utilize these devices for studying environmental nitrate levels, conducting experiments, and monitoring water quality.

Nitromaters become unsung heroes in the laboratory, working silently to unravel nitrate mysteries and contributing crucial data for scientific investigations. Their precision and reliability make them essential instruments for understanding and addressing environmental and water-related challenges.

Benefits And Advantages Of Nitromater – Let’s Take A Look!

- Optimized Combustion: Nitromater stands out for its ability to enhance the efficiency and performance of engines and machinery.

- Improved Power Output: By optimizing combustion processes, Nitromater contributes to improved power output, enhancing the overall performance of engines.

- Fuel Efficiency: Nitromater is known for its role in improving fuel efficiency, making it a valuable component in various applications.

- Lower Emissions: Nitromater technology is celebrated for its positive environmental impact, as it leads to lower emissions during combustion processes.

- Cleaner Combustion: The use of Nitromater results in a cleaner combustion process, reducing pollutants and contributing to a more environmentally friendly operation.

- Carbon Footprint Reduction: By minimizing emissions and promoting cleaner combustion, Nitromater aids in reducing the carbon footprint of machinery and vehicles, aligning with sustainability goals.

Read: Habine – Let’s Discover Now In 2024!

Challenges And Limitations In Nitromater Technology – Take Analysis!

While nitromater technology brings a host of advantages, it is not without its share of challenges and limitations that require careful attention. One significant challenge faced by nitromater technology is the intricate process of implementation and integration into existing systems.

The complexity arises from compatibility issues and the need for system adjustments, posing obstacles that must be addressed for the widespread adoption of this technology. The technical constraints associated with seamlessly integrating nitromater into diverse systems necessitate thorough consideration and strategic solutions.

Safety concerns present another formidable challenge in the realm of nitromater technology. The handling and storage of nitrogen-based compounds, integral to their functionality, require meticulous attention due to potential risks.

Ensuring proper safety protocols and measures becomes crucial to mitigate the risks associated with these compounds, safeguarding against accidents and ensuring secure storage practices. The need for rigorous safety measures adds an extra layer of complexity to the operational landscape of nitromater technology.

Read: Nodokayoayo – Find The Mystery and Charm!

Frequently Asked Questions:

1. How has Nitromater evolved?

Nitromater has undergone a remarkable evolution from its humble beginnings, progressing from basic forms to highly advanced instruments capable of precise analysis. Technological advancements, including sophisticated sensors, data analysis algorithms, and enhanced materials, have played a crucial role in this evolution.

2. What are the key components of Nitromater?

The core components of Nitromater include sensors, analyzers, and data display units. These elements work together to detect and measure nitrate concentrations accurately, resembling a mini-laboratory packed into one sleek device.

3. How does Nitromater work in industrial applications?

In industries such as agriculture, water treatment, and food production, Nitromaters play a crucial role in monitoring and controlling nitrate levels. They act as vigilant guardians, ensuring that nitrate content in industrial processes remains within acceptable limits, contributing to overall efficiency and compliance.

4. What are the applications of Nitromater in research and science?

Nitromaters are invaluable tools in research and science, used for studying environmental nitrate levels, conducting experiments, and monitoring water quality. They silently work in laboratories, contributing crucial data for scientific investigations and addressing environmental and water-related challenges.

5. What benefits does Nitromater offer in terms of efficiency and performance?

Nitromater enhances the efficiency and performance of engines and machinery by optimizing combustion processes. It improves power output and fuel efficiency, making it a valuable component in various applications.

6. How does Nitromater contribute to environmental sustainability?

Nitromater technology has a positive environmental impact by leading to lower emissions during combustion processes. It results in cleaner combustion, reducing pollutants and contributing to a more environmentally friendly operation.

Conclusion:

To sum up, nitromater technology is changing industries and leading innovation for a better future. By learning about its history, features, uses, and challenges, we get important insights into what this advanced technology can do.

Read more: